FAQ of WISCHEMANN Kunststoff GmbH

General information

What exactly does WISCHEMANN do?

WISCHEMANN Kunststoff GmbH is an internationally successful manufacturer of innovative thermoformed parts for the construction industry and the heating and sanitary sector. Our products include, for example, drainage mats for green roofs and dimpled sheets for underfloor heating systems. From the raw material to the finished product, the entire production process takes place under one roof. This is ensured by the WISCHEMANN team of around 150 colleagues.

Who belongs to the WISCHEMANN Group?

In addition to WISCHEMANN Kunststoff GmbH, the WISCHEMANN Group also includes VACU-form WISCHEMANN GmbH & Co. KG in Salzbergen and wi-sales GmbH in Ochtrup, all located in north-west Germany.

Products and production

For which industries does WISCHEMANN manufacture plastic parts?

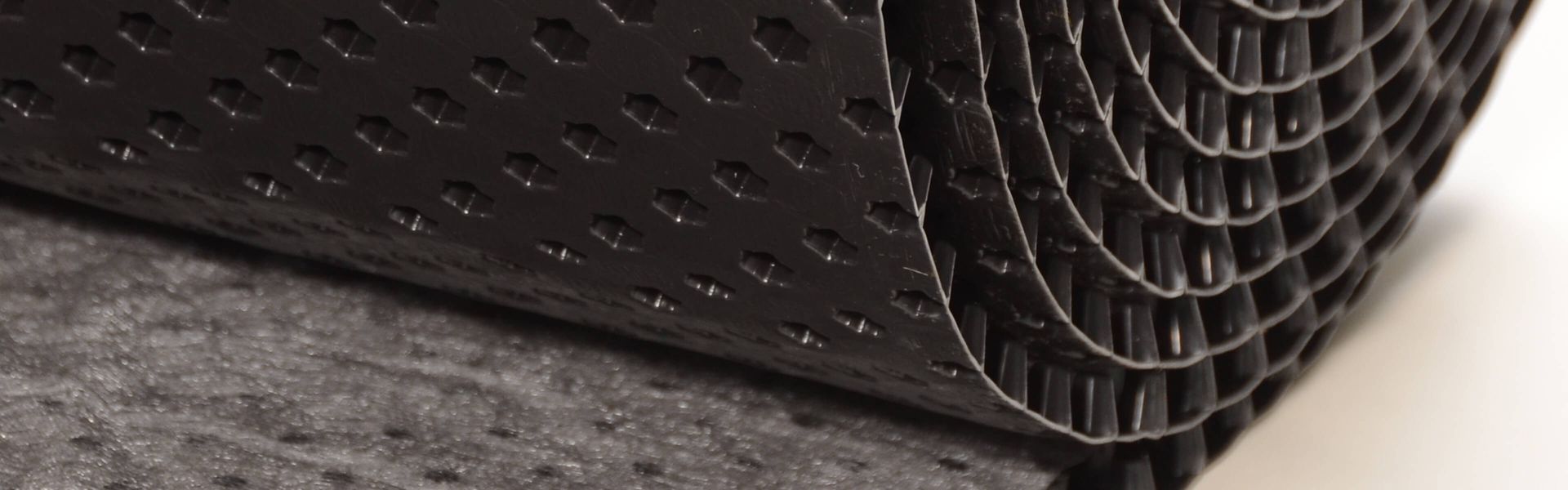

WISCHEMANN Kunststoff GmbH mainly produces system and dimpled sheets as well as drainage sheets for the construction industry and the heating and sanitary sector. These thermoformed parts are used as the basis for surface temperature control systems (underfloor heating) or as drainage mats for green roofs.

Which plastics does WISCHEMANN process?

At WISCHEMANN we use polyethylene (PE), polypropylene (PP), polystyrene (PS) and also expanded polystyrene (EPS), depending on the product. Within the WISCHEMANN Group, we also use ABS, PMMA and PC.

What product dimensions are possible with thermoforming?

Within the WISCHEMANN Group, we can produce thermoformed parts up to a size of 4.60 m x 2.80 m x 1 m.

What quantities are possible at WISCHEMANN?

The possible quantities always depend on the product. Please feel free to contact us!

How sustainable are WISCHEMANN products?

Our sustainability endeavours have many facets. At WISCHEMANN, for example, we only process recyclable thermoplastics and minimise waste by almost completely recycling our milling and punching waste. Around 70% of the materials we use are made from recycled materials. We now also use REDcert²-certified bio-EPS for the production of system panels for underfloor heating systems. In addition, we have only been using electricity from renewable sources since 2016. Compared to the electricity mix, this has enabled us to reduce the average CO2 values per square metre of a WISCHEMANN product by around 90%, which corresponds to a saving of around 3,000 tonnes of CO2 in 2024. You can find out more about this topic on the Environmental protection subpage.

Which process does WISCHEMANN use for plastics processing?

WISCHEMANN Kunststoff GmbH is a specialist in the development and production of innovative thermoformed parts with a high level of vertical integration on self-developed and patented systems.

In our inline production line, for example, the PP granulate is mixed with a colour batch in the extruder and heated. The melt is then extruded onto a moulding line, where it is thermoformed as a dimpled sheet in a vacuum thermoforming process and bonded to the 450-gram nonwoven when hot.

Career

What jobs is WISCHEMANN currently offering?

All current vacancies can be found on our jobs page. We are also happy to accept unsolicited applications. As we require German language skills for the jobs, the job advertisements are only available in German.

Directions and logistics

How do I find my way to WISCHEMANN?

WISCHEMANN Kunststoff GmbH is based in north-west Germany. The head office is located at Am Langenhorster Bahnhof 2 in 48607 Ochtrup. There are also other locations such as external warehouses.

What are the loading times for deliveries and collections?

Our loading times for lorries are Monday to Thursday from 07:30 to 15:00 and Friday from 07:00 to 12:00. Please make an appointment in advance.